QUALITY TEST EXPERIMENT

Comprehensive quality control: rigorous testing from raw materials to finished products

1.5M

Drop Test

The simulated product may be subject to a drop, after three 1.5 meter drop tests, the water bottle didn’t disintegrate or break.

50,000 Times

Fatigue Test

Use professional press for multiple openings and closings to ensure product life and durability.

360°

Leak Test

The simulated product experienced a bumpy scene, and performed 360° high-speed rotation. The test results showed no leakage.

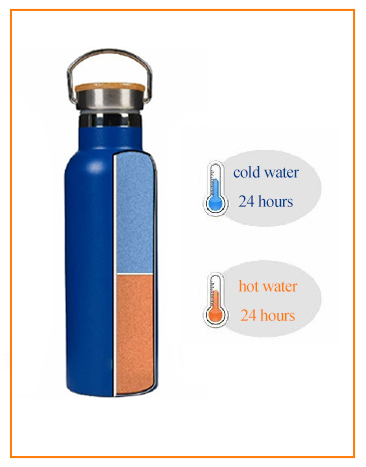

24 Hours

Temperature Test

Place the water bottle in an environment of +100° and -25° for 24 hours to test the product’s thermal or cold insulation performance.

BPA Free

Material Test

Test whether the water bottle material meets food-grade environmental protection standards and will not breed bacteria or produce odor.

100% Adhesion

Appearance Test

Test water bottle printing quality, surface treatment durability, etc. to ensure beautiful appearance and durability.

WHAT CUSTOMERS SAY

Unfiltered Feedback: Genuine 5-Star Reviews from Satisfied Clients

UAE

USA

IT